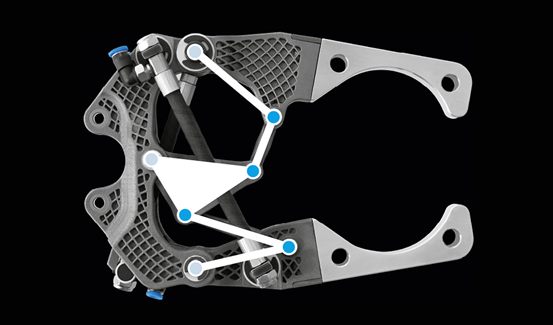

The PowerGripper is modelled on the complex kinematics of the bird’s beak. In mechanical terms, this is known as Watt’s linkage. In the PowerGripper project, the developers implemented this bionic principle using the DMSP-5 Fluidic Muscle from Festo.

Optimised force-to-weight ratio

With this Watt’s linkage, relatively large opening strokes can be realised within a highly compact installation space. Thanks to the lightweight structure, along with the the very light pneumatic muscle and a titanium alloy as the material for the basic components, the PowerGripper from Festo attains a very favourable force-to-weight ratio.

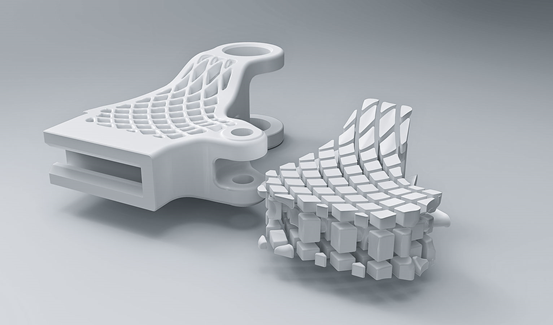

Unique form-finding with generative manufacturing

The lightweight structures on the interior and exterior of the PowerGripper are designed in accordance with the forces acting on the component and can only be produced in this form by means of the metal laser sintering process, in which the metallic powder is melted, layer by layer, by means of a laser beam controlled by 3D CAD data. This provides unique opportunities in form-finding and allows individualised 3D printing of complex products.

Information Source: https://www.festo.com/group/en/cms/10237.htm