引文信息:

Xuefei Li, Zhiwei Guo, Qiren Huang & Chengqing Yuan . Insight into the Lubrication Performance of Biomimetic Porous Structure Material for Water-lubricated Bearings. Journal of Bionic Engineering,2023,20(5),1905 - 1916.

Insight into the Lubrication Performance of Biomimetic Porous Structure Material for Water-lubricated Bearings

Xuefei Li, Zhiwei Guo, Qiren Huang & Chengqing Yuan

1 School of Transportation and Logistics Engineering, Wuhan University of Technology, Wuhan, 430063, China

2 National Engineering Research Center for Water Transport Safety, Reliability Engineering Institute, Wuhan, 430063, China

Abstract

Water-lubricated bearings have great advantages in the application of ship tail bearings due to the characteristics of green, pollution-free, and sustainable. However, the poor wettability of water-lubricated materials, as well as the low viscosity and poor load-carrying capacity of water, resulting in poor lubricating film integrity and short material service life under low-speed, heavy-load, start-stop conditions, which limits its application. To study the relationship between wettability and lubrication state and improve the lubrication performance of Si3N4 under water lubrication conditions, the characteristic parameters that determine the hydrophilicity of Sphagnum were detected and extracted, and the bionic Si3N4 model was established using Material Studio. Then, the molecular dynamic behavior and tribological properties of different Si3N4 models were simulated and analyzed. Pore structure affects the spreading and storage of water on the material surface and changes the wettability of the material. Under the condition of water lubrication, better wettability and water storage promote the formation of water film, effectively improve the lubrication state of the material, and improve its bearing performance.

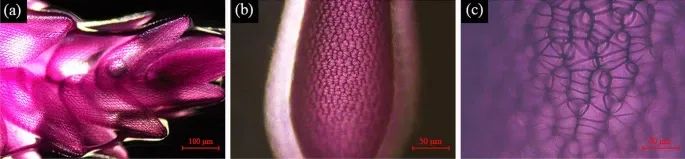

Fig. W1 Optical microscope images of Sphagnum plants (a) and leaves (b, c) at different magnifications.

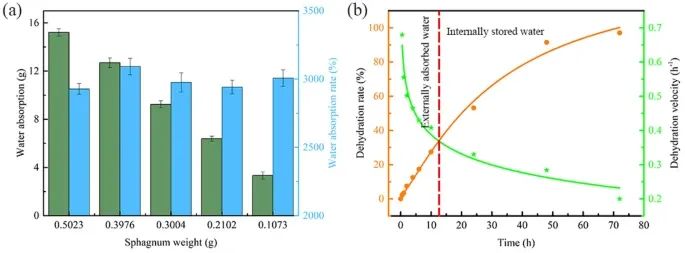

Fig. W2 Water absorption (a) and water retention (b) of Sphagnum with different weights.

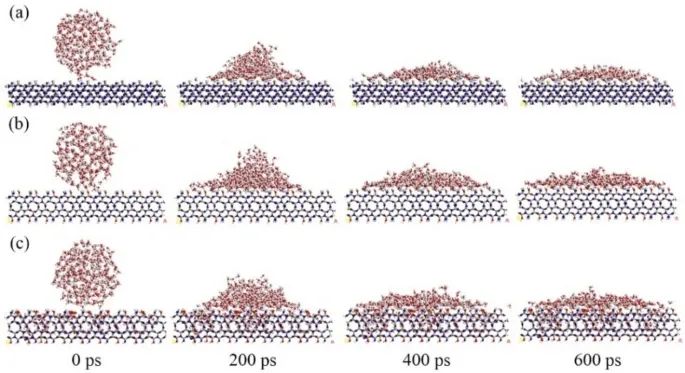

Fig. W3 Wetting simulation process of amorphous Si3N4 (a), –OH modified Si3N4 (b), biomimetic Si3N4 (c).

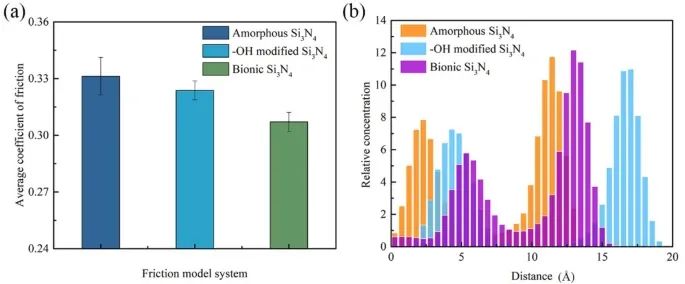

Fig. W4 Average coefficient of friction (a) and relative atomic concentration (b) for different lubricating systems .

Information Source: https://mp.weixin.qq.com/s/r5tmWaTth_U8YpW7s5JEQw