2D and 3D COFs embedded with multiple macrocycle-chelated non-precious metal complexes, inspired by the catalytic centers of natural coenzymes and cofactors, have been synthesized and investigated to address a key question in the research of air-cathode DMFC and MFC.

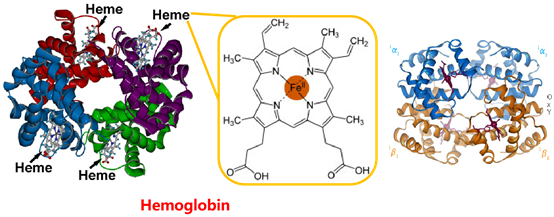

Hemoproteins have diverse biological functions including the transportation of diatomic gases, chemical catalysis, and electron transfer. The best-known hemoprotein is hemoglobin (the red pigment in blood). Heme is the key prosthetic group for hemoglobin and its core structure is iron porphyrins. With the synergistic action of histidine located adjacent to heme, heme can bind O2 and form oxyhemoglobin in lung, where the pH is high and CO2 concentration is low. The bound O2 will be released in the tissues where the situation is reversed.

Figure 1. Schematic of Hemoproteins and Hemoglobin. The coenzymes and cofactors in hemoglobin often contain macrocyclic metals

and play critical roles in oxygen transportation and redox chemistry in many organisms.

We synthesized a conjugated microporous metalloporphyrin framework (CoPEF)through alkyne metathesis polymerization and mixed with carbon black, a low-cost conductivity enhancer, to obtain the composite electrocatalyst of CoPEF/C. CoPEF/C shows excellent ORR catalytic activity in both acidic and alkaline media. Compared to discrete metalloporphyrin monomers (M1),the conjugated framework exhibits considerably enhanced ORR catalytic activity in terms of onset potential and current density under otherwise identical conditions, which is likely due to the high porosity and conjugated nature of the framework, leading to better exposure of active sites and efficient electron and mass transport. Importantly, the CoPEF/C catalyst is able to achieve the full reduction of 02 via a 4-electron pathway. The catalyst also shows superior durability and enhanced resistance to methanol-poisoning compared to the composite containing the monomer M1,further suggesting the potential of such a polymer catalyst in DMFC applications.

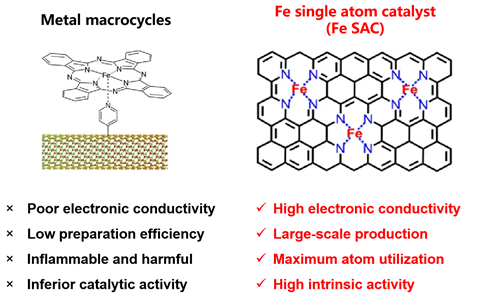

Figure 2. The principle of bionic Fe-N4 structure for oxygen reduction reaction.

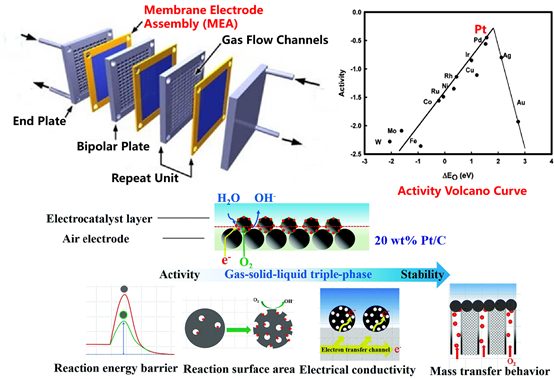

Figure 3. The design principle of electrocatalysts and three-phase interfaces for oxygen reduction reaction.

To date, Pt-based catalysts are still the most widely used ORR electrocatalysts. However, the scarcity, high cost, and vulnerability to poison have strongly hindered the industrialization of Pt-based catalysts. Our work represents the first application of alkyne metathesis polymerization for the synthesis of ordered redox active organic frameworks. It is conceivable that such an approach could lead to the development of cost-effective alternatives of Pt/C for fuel cells, thus greatly facilitating practical applications of this emerging technology.

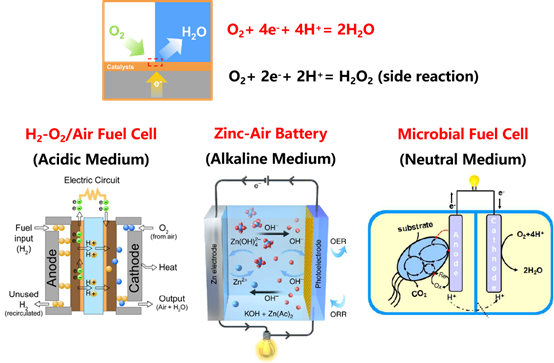

Figure 4. Application of ORR electrocatalysts in H2-O2/air fuel cells, zinc-air batteries, and microbial fuel cells.

[1] Wu ZS, Chen L, Liu JZ, Parvez K, Liang HW, Shu J, et al. High-Performance Electrocatalysts for Oxygen Reduction Derived from Cobalt Porphyrin-Based Conjugated Mesoporous Polymers. Adv Mater. 2014;26:1450-5.

[2] Lin L, Zhu Q, Xu AW. Noble-Metal-Free Fe-N/C Catalyst for Highly Efficient Oxygen Reduction Reaction under Both Alkaline and Acidic Conditions. J Am Chem Soc. 2014;136:11027-33.

[3] Cao R, Thapa R, Kim H, Xu X, Kim MG, Li Q, et al. Promotion of oxygen reduction by a bio-inspired tethered iron phthalocyanine carbon nanotube-based catalyst. Nat Commun. 2013;4.

[4] Lu GL, Zhu YL, Xu KL, Jin YH, Ren ZJ, Liu ZN, et al. Metallated porphyrin based porous organic polymers as efficient electrocatalysts. Nanoscale. 2015;7:18271-7.

[5] Lu GL, Zhu YL, Lu L, Xu KL, Wang HM, Jin YH, et al. Iron-rich nanoparticle encapsulated, nitrogen doped porous carbon materials as efficient cathode electrocatalyst for microbial fuel cells. J Power Sources. 2016;315:302-7.

[6] Lu GL, Yang HS, Zhu YL, Huggins T, Ren ZJ, Liu ZN, et al. Synthesis of a conjugated porous Co(II) porphyrinylene-ethynylene framework through alkyne metathesis and its catalytic activity study. J Mater Chem A. 2015;3:4954-9.

Xinliang Feng

ChoAn-Wu Xu

Meilin Liu

Jaephil Cho