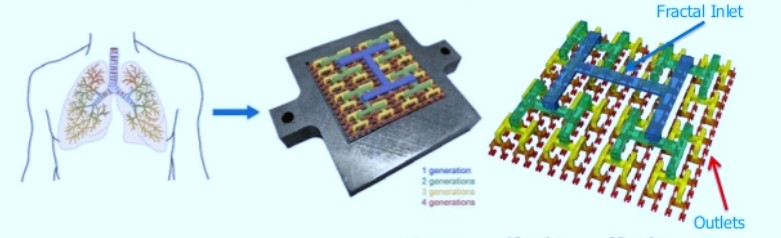

A lung-inspired approach is employed to overcome performance issues in proton exchange membrane fuel cell. The fractal geometry of the lung is used as the model to design and optimize flow-fields of different branching generations, processed by 3D printing technology, resulting in uniform reactant distribution and effective discharge of liquid water.

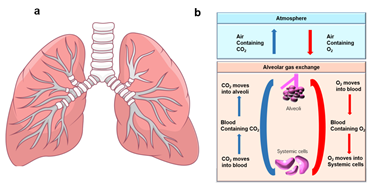

The lung is one of the most important organs in the respiratory system, and its main function is to transmit and exchange gases in the human body. The bronchi in the lungs branch repeatedly into numerous tree-like bronchioles, whose ends swell into alveoli. Through diffusion effect, the alveoli and the capillaries exchange oxygen and carbon dioxide. By controlling the pressure difference generated by the changes of pressure and atmospheric pressure in the lungs, the lungs absorb O2 and expel CO2, realizing the gas exchange process between people and the outside world

Figure 1 Lung model and Mass transfer mechanism. (a) Lung model, (b) Mass transfer mechanism

Simulate the geometric fractal structure distribution of the lungs and design a tree-shaped geometric fractal flow channel. In this design, the branch flow channels are numerous and widely distributed, and the airflow enters the flow channel and is in full contact with the membrane electrode diffusion layer along the branch channel. Numerous branch channels make the fluid in the flow channel disperse, the velocity of the fluid is appropriately slowed down, the reaction gas can be evenly distributed, and the entropy value of the system is reduced. The water generated by the electrochemical reaction of the cathode catalytic layer will change the cross section of the tree-shaped geometric fractal flow channel, change the flow velocity, accelerate the movement of the reaction accumulation water, effectively discharge the water generated by the reaction, and realize the mass transfer. The pressure drop is small at the inlet and outlet of the runner, and the parasitic power loss is small, which improves battery performance.

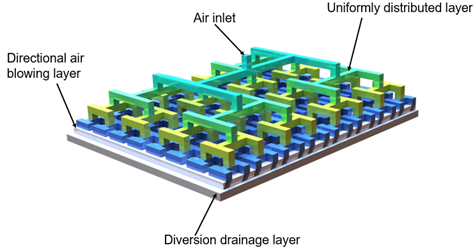

Figure 2 Mechanism of action of bionic lung multi-layer structure fuel cell

The design of the flow field is the key to determine the performance of the proton exchange membrane fuel cell. The traditional flow channel design has problems such as large pressure drop, large parasitic power loss, uneven distribution of reactants, and incapable discharge of water generated by the reaction, which may affect the performance of the proton exchange membrane fuel cell and even cause damage. It is an important research issue which design high-efficiency drainage and low-pressure drop new flow channels in the research of proton exchange membrane fuel cell fuel cells. Based on the bionic idea of natural design, the 3D printing technology is based on the lung bionic tree-shaped geometric fractal flow channel, which reduces the pressure drop of the channel inlet and outlet, improves the drainage efficiency, reduces the power loss, improves the performance of the proton exchange membrane fuel cell fuel cell, and better serves New energy vehicles, etc.

Figure 3 Bionic lung multi-layer structure fuel cell bipolar plate

[1]Trogadas P, Cho J I S, Neville T P, et al. A lung-inspired approach to scalable and robust fuel cell design[J]. Energy & Environmental Science, 2018, 11(1): 136-143.

[2]Kloess J P, Wang X, Liu J, et al. Investigation of bio-inspired flow channel designs for bipolar plates in proton exchange membrane fuel cells[J]. Journal of Power Sources, 2009, 188(1): 132-140.

[3]Cho J I S, Neville T P, Trogadas P, et al. Visualization of liquid water in a lung-inspired flow-field based polymer electrolyte membrane fuel cell via neutron radiography[J]. Energy, 2019, 170: 14-21.

[4]Asadzade M, Shamloo A. Design and simulation of a novel bipolar plate based on lung‐shaped bio‐inspired flow pattern for PEM fuel cell[J]. International Journal of Energy Research, 2017, 41(12): 1730-1739.

[5] Dong J H, Liu S F. Numerical simulation of fractal tree-shaped flow field structures in PEMFC[C]//Applied Mechanics and Materials. Trans Tech Publications, 2012, 151: 32-35.

BaoLian Yi;Mu Pan; Marc-Olivie